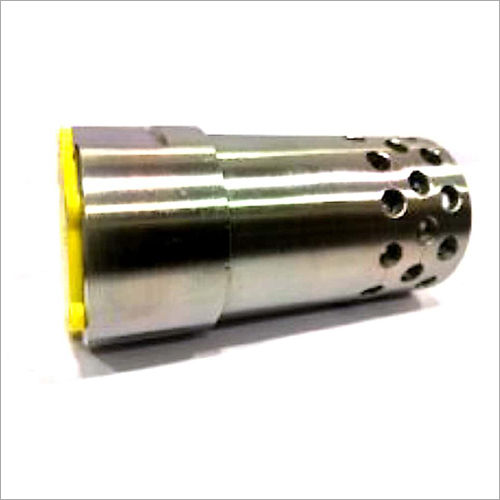

सà¥à¤à¥à¤¨à¤²à¥à¤¸ सà¥à¤à¥à¤² सà¥à¤ वालà¥à¤µ

सà¥à¤à¥à¤¨à¤²à¥à¤¸ सà¥à¤à¥à¤² सà¥à¤ वालà¥à¤µ Specification

- मटेरियल

- स्टेनलेस स्टील

- स्टाइल

- Straight Material: Stainless Steel Connection: Threaded Shape: Round Type: Needle Valve Port Size: 1/4 Inch Technique: Forged Head Code: Hex Pressure: Up to 6000 PSI Application: Gas, Liquid, and Oil Flow Regulation

सà¥à¤à¥à¤¨à¤²à¥à¤¸ सà¥à¤à¥à¤² सà¥à¤ वालà¥à¤µ Trade Information

- Minimum Order Quantity

- 10 टुकड़ाs

- आपूर्ति की क्षमता

- प्रति सप्ताह

- डिलीवरी का समय

- दिन

About सà¥à¤à¥à¤¨à¤²à¥à¤¸ सà¥à¤à¥à¤² सà¥à¤ वालà¥à¤µ

Engineered for Leakproof Performance

Designed with a robust stainless steel body and high-quality PTFE packing, this needle valve ensures a leakproof operation. The polished finish and non-rotating stem prevent both external and internal leakage, making it reliable for critical gas, liquid, and oil flow applications.

Versatile and High-Pressure Capabilities

Able to withstand pressures up to 6000 PSI, the valve is forged for durability and compatible with temperature ranges from -20C to 220C. Its threaded female end and replaceable seat allow for flexible installation and easy service, while the SS304/SS316 construction ensures chemical resistance.

Precision Flow Regulation

Equipped with a T-bar handle and a straight, round design, the valve provides accurate flow control. The non-rotating stem offers check-free operation, making it suitable for settings where delicate regulation of fluid or gas is essential.

FAQs of Stainless Steel Needle Valve:

Q: How does the SS304/SS316 construction benefit the needle valves performance?

A: The high-grade stainless steel body provides excellent corrosion resistance and durability, making the valve suitable for harsh industrial environments and ensuring longevity in regulating gas, liquid, or oil flows.Q: What is the recommended application for this needle valve?

A: This valve is designed for precise regulation of flow in gas, liquid, and oil systems, commonly used in chemical processing plants, laboratories, and fluid control industries due to its high-pressure and temperature capabilities.Q: When should the seat of the valve be replaced?

A: The replaceable seat should be exchanged when there is noticeable wear, leakage, or decreased performance during operation, ensuring continued efficiency and safety in the system.Q: Where can this needle valve be installed?

A: It can be installed in pipelines matching its 1/4 inch female threaded hex connection, suitable for both new and existing setups where reliable, leakproof flow control is required.Q: What is the process for maintaining the leakproof construction?

A: Routine inspection and servicing of the PTFE stem packing and seat are recommended. This maintenance ensures the valve retains its leakproof function and extends its operational lifespan.Q: How does the non-rotating stem enhance valve operation?

A: The non-rotating stem prevents stem wear and reduces friction within the packing, resulting in smoother operation, less maintenance, and extended seal life, especially in high-cycle applications.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in Industrial Valve Category

फ्लोट वाल्व

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 510

मटेरियल : स्टेनलेस स्टील

मूल्य की इकाई : टुकड़ा/टुकड़े

मूल्य या मूल्य सीमा : आईएनआर

स्टाइल : Industrial Material: Stainless Steel Connection: Threaded Shape: Spherical Type: Float Valve Port Size: 1 inch Technique: Precision Casting Head Code: Round Pressure: Medium Pressure Application: Water Tank

एसएस फ्लैंग्ड एंड फुट वाल्व

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 10

मटेरियल : स्टेनलेस स्टील

मूल्य की इकाई : टुकड़ा/टुकड़े

मूल्य या मूल्य सीमा : आईएनआर

स्टाइल : Flanged End Material: Stainless Steel Connection: Flanged Shape: Cylindrical Type: Foot Valve Port Size: 5 inch Technique: Precision Casting Head Code: Round Pressure: Medium Pressure Application: Industrial / Water Pump Suction Line

एसएस थ्रेडेड फुट वाल्व

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 510

मटेरियल : ,

मूल्य की इकाई : टुकड़ा/टुकड़े

मूल्य या मूल्य सीमा : आईएनआर

स्टाइल : Threaded

फ्लोट वाल्व

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 510

मटेरियल : ,

मूल्य की इकाई : टुकड़ा/टुकड़े

मूल्य या मूल्य सीमा : आईएनआर

स्टाइल : Industrial

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें